This was an impulse purchase. Last week I had ventured out to a gun store that I only infrequently visited and as I was about to leave, happened to see that they had a selection of Glock knives including one that matched the same color of polymer frame for my Glock 34 pistol. So, after an interminable wait at the counter to try and get them to take my money, I was finally able to leave the store with my new purchase. I paid $39 for my model, which is a little on the high side for the knife as I've seen them for as low as $32 on various websites (although shipping costs may bring the final cost to parity with what I paid).

I didn't really know much about the Glock knife before this. I'd seen them at stores, gun shows, and the occasional ad on a website; I knew that they came with or without a saw on the spine; and I knew that this knife was actually Glock's first foray into building weapons. But there is a quite a bit more to them.

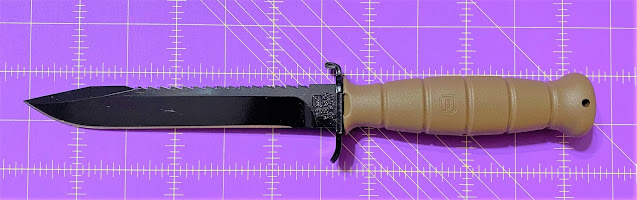

First of all, they are actually bayonets developed for use with the Steyr AUG rifle with a bayonet adaptor. There is a polymer cap on back of the knife's handle that if removed (and note that removing it typically means the destruction of the cap) reveals a short, metal lined tube that is designed to fit over the bayonet adaptor. (If you do want to use the hollow portion to carry stuff, here is a link to a video of a guy that threaded the tube to accept a bolt). As you will notice from the photographs, the upper part of the cross-guard is bent over at a 90 degree angle. Although you will find those that say this was so the knife could be used as a bottle opener (and it can, in fact, be used that way), it was bent over like that to fit under and against the barrel of the AUG when it is used, in fact, as a bayonet.

There are two models of the Glock knife. The first and oldest model is the FM 78 model with the plain spine on the blade. The second model is the FM 81 which has a root saw on the back of the spine. Other than that, the two models are identical. The numbers correspond to the year each was accepted into service: 1978 and 1981, respectively.

Glock offers the knives in various colors that match up with the more common frame colors they have released for their pistols. I purchased the FM 81 not because I wanted the saw (I didn't, actually) but because that is what they carried at the store.

As you can see from the photograph above, the knife's overall length is approximately 11.5 inches, and it sports a 6.5 inch blade, although the sharpened portion is about an inch less at 5.5 inches. The overall blade shape is a clip point. The blade thickness is approximately 0.22 inches thick and because of the style and geometry of the point, it retains this thickness very close to the tip of the blade, making the tip very strong and suitable for piercing things.

I was not able to find anything definitive about the blade material other than it is a high carbon steel with a Rockwell hardness of about 55. Quite a few sites and YouTube channels indicate that it is a 1095 spring steel, or something similar. While I don't know where they got that information, I would not at the least be surprised as that is a popular steel for sword makers because it is strong yet retains enough flex to take a hard jarring blow without breaking. The Rockwell hardness of 55 makes for a steel hard enough to retain an edge, but still relatively easy to sharpen. Although a lot of people like knives that are harder, the trade off is a blade that is at a great risk of breaking if bent or struck a sharp blow.

The blade itself is nicely shaped and finished and comes to a uniform, symmetrical point that is unusual for the price point. Conversely, the cross-hilt is formed out of a thick sheet steel that does not appear to have any smoothing or touch up to it before it was coated. Not pretty but it is functional. Although I have not tried it, my research on this knife indicates that the combination of the spring steel and the strong point make this knife a decent throwing knife.

The blade and cross-hilt are uniformly coated with what appears to be some sort of baked on finish; I've read it described as a phosphate coating. It is semi-gloss finish, whatever it is, which makes it smooth--almost slick--to the touch.

The knife comes working sharp from the factory. Mine had been over sharpened on one side leaving a burr down the length of the edge, but this was quickly touched up with my Lansky sharpener. For those of you interested, the angle of the grind appears to be 25 degrees. At least that is what I used and it quickly brought it to be sharp enough to shave off some hairs.

As mentioned above, the spine has saw teeth machined into it for some minimal sawing tasks. I've seen it described as a root saw (for cutting roots that might be encountered when digging a fox hole or a trench) but in one of videos to which I've linked below, the reviewer indicated that it was about perfect for making the notches needed for the triggers used in improvised traps and snares.

The teeth engage with a forward push of the blade. Running my hand backward on the knife it was bumpy, of course, but did not catch on my hand. Thus, should you bury the knife blade into something, the saw teeth should not impede pulling the knife back out. The smooth coating will also help.

The knife handle is polymer and comfortably shaped. It is only lightly textured, however, so it might be slippery if wet or covered with blood. The hilt is large enough, however, that it should keep your hand from slipping over the blade if you had to stab it into something or were using it while wet.

There is no lanyard loop on the knife handle. There are two holes at the back, but they do not go all the way through the handle and it is not clear what is there function. I suppose someone with the right tools and a torch could fashion a metal D-loop so that the two ends would fit into these holes to fashion a lanyard attachment if they so wished.

The sheath is, of course, polymer and matches that used in the knife handle. It is thick and undoubtedly will protect the knife.

It is not a Kydex sheath by any means, however. That blade is instead kept in place by the polymer clip or tab molded into the sheath that locks into a notch just behind the cross-hilt when the knife is fully inserted into the sheath. You can see more detail of this in the photograph immediately below.

Because of the nature of the tab and how it locks, the sheath can be worn on either side (left or right) and the knife need only be flipped into the correct orientation. Also, the system is ambidextrous, so the knife can be released using either hand.

I can assure you, however, that the knife is not going to easily come loose. It takes quite a bit of force applied underneath the tab to release the knife. In fact, trying it one handed, my first couple of attempts gave me a broken nail and sore thumb. There is a trick to release it while holding onto the knife handle which involves both shoving your thumb underneath the tab while at the same time pushing it slightly to the side.

Otherwise, what I found can work is to wrap your forefinger under the hilt to give leverage and then use the side of the thumb to force up the tab. You aren't gripping the handle, but it at least releases the knife from the tab so you can then readjust your grip and pull the knife out of the sheath.

The knife is designed to fit over a belt using the belt loop shown above. You can either slide a belt through the loop, or unlock the loop, fit it over the belt, and lock it again. To unlock the loop, simply push the end of the loop sideways until it clears the clip. Locking is the reverse of that.

At the other end of the sheath, there is a molded loop so that you can tie down the end of the sheath--around you leg, I presume. There is no cord included for this purpose, but I assume a length of paracord or a boot lace would work.

Finally, at the very tip of the sheath is a very generous drain hole. This is especially appreciated when using a carbon steel knife blade.

I've included some videos below that I came across when researching the knife to prepare this review. The first, which I had posted earlier this week, is from FerFal in which he argues that the Glock knife may be the perfect knife for a prepper/survivalist. I've also included a video going through a torture test of the knife.

The gist of these videos is that this is a knife that, while it may not excel as a woodcraft knife or as a fighting knife, does both tasks reasonably well.

That is, it is not quite big enough as a chopper, but the spine is thick enough and the blade tough enough that you can use it for batonning to split wood. It certainly can handle other camp chores such as making feather sticks, cutting or whittling wood, and cutting cordage; and there is the saw blade on the 81 model that you can use for limited wood processing. The blade is probably a bit too long for a good hunting knife, but not so long that it could not be pressed into that role, I suppose. And, as noted above, the tip is strong--strong enough to pierce through cans and light sheet metal as one of the videos demonstrates.

It is perhaps a bit short for a fighting knife, in my opinion--at least one with some chopping capabilities like some of the more famous fighting knives like the Bowie or the Kukri. However, the blade shape is ideal for stabs and thrusts. My concern in this regard is the saw back spine on the Model 81 which I would be concerned might get hung up on flesh or bone. Not an issue, of course, if you get the Model 78.

Add to this that it appears to be a well made knife and sheath, particularly at the price point, which makes it inexpensive enough to have one for each member of your family or group, or to keep some in reserve.

Below are some of the video reviews I came across which provide some additional details or tests of the knife:

Annnnnd? Do you like it?

ReplyDeleteI don't know yet. It is certainly a sturdier knife than I expected, yet also much lighter than other combat/field knives. But I haven't really had an opportunity to use it for anything. I want to test it a bit and carry it around.

Delete